- Industry: University

- Region: Europe

WUR Autonomous Greenhouse: Gardin Plant Feedback Generates Extra €200k/ha/yr

- 44kg

per m2 per year - 35%

higher profitability

Summary

- Achieved 44kg/m2/year 30% higher production than reference grower

- 35% higher profitability than reference

- Highest dry matter content and yield per pot

Validation of Bioautonomous Growing

Climate change is destabilising agriculture whilst the demand for affordable fresh produce accelerates. Protected cropping in modern glasshouses can help, but scaling is limited by a shortage of skilled growers. Autonomous control offers the ability to unlock high-yielding farms anywhere in the world, however, implementations so far have revealed the difficulty in accurately accounting for the crop response.

Autonomy in greenhouses is particularly challenging because the inside climate, outside weather, and plant response form a tightly coupled non-linear dynamic system: small changes in light, temperature, or humidity cause highly complex changes in plant dynamics. Real-time measurements of photosynthetic performance provide a direct signal of plant status, allowing control strategies to adapt to the physiology rather than relying only on environmental proxies.

Gardin uses a technique called chlorophyll fluorescence to measure the efficiency of plant photosynthesis in real time. As part of team MuGrow (a collaboration between TU Delft, Gardin, and Rijk Zwaan), Gardin competed in the 4th Autonomous Greenhouse Challenge; the first edition to require full autonomy from potting to harvesting. Teams controlled a greenhouse compartment of dwarf cherry tomato, a crop well suited for robotic harvesting and similar to many potted plant and cut flower species.

MuGrow's algorithm was inspired by how growers make decisions today. Each morning, growers walk through the greenhouse to observe the crop, monitor current production forecasts, and then make necessary adjustments to their climate strategy. MuGrow's architecture mimicked these steps using Gardin's sensor for biofeedback, model predictive control for optimisation, and reinforcement learning for long-term targets.

The results are an exciting validation of this approach. MuGrow achieved the highest yield per pot (340 gram/pot), highest quality (7.3% dry matter), and shortest cycle (69 days); equivalent to 44 kg/m2/year. This is a 45% increase in annual production compared to the industry average of 30 kg/m2/year for typical high-wire cherry tomatoes and 30% higher than the reference grower in the challenge. Assuming a farm-gate price of €2/kg, MuGrow generated an additional €200,000/ha value per year compared to the reference. Moreover, MuGrow's profit was 35% higher, increasing to 60% with optimised harvest timing.

MuGrow's algorithm was a proof of concept in collaboration with the Delft Center for Systems and Control but Gardin's sensor is already commercially available. This report focuses on the biofeedback aspect of the MuGrow algorithm through the lens of Gardin's Plant Indicators. Whilst growers may not be adopting full autonomy today, they are already leveraging Gardin's insights as feedback for their own strategies and achieving similar improvements to their production.

| Compartment | MuGrow | Reference | % Diff |

|---|---|---|---|

| Annual Yield (kg/m2/yr) | 44 | 34 | +30% |

| Dry Matter Content (%) | 7.3 | 6.6 | +10% |

| Profit (€/pot) | 0.18 | 0.13 | +35% |

| Profit at Optimum (€/pot) | 0.27 | 0.17 | +60% |

Gardin Plant Indicators - Feedback for Growers

Gardin offers four novel indicators to help growers monitor plant performance. These same indicators were incorporated into the MuGrow control algorithm to guide critical aspects of the cultivation strategy including lighting, shading, and CO₂ enrichment. By maintaining these indicators at optimal levels, growers can achieve exceptional outcomes for their crop.

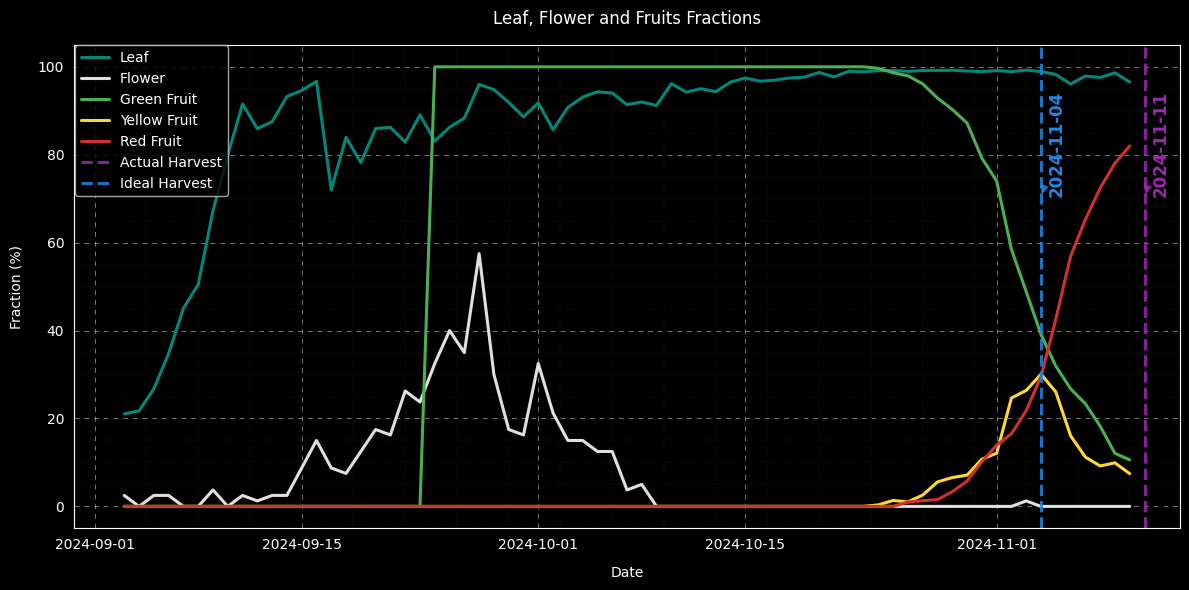

All teams were required to use computer vision models for autonomous physical phenotyping, to monitor the crop's long-term development. MuGrow developed multiple models to classify plant growth stages (vegetative, flowering, fruiting), determine pot spacing, and trigger harvesting autonomously.

Competition rules maximised revenue at 150 grams of red fruit per pot, but like all other teams, MuGrow delayed harvest until roughly 250 grams per pot as a safety precaution. This delay resulted from overly strict guardrails on the computer vision algorithms—harvesting 7 days earlier would have increased annual profit by 50% due to faster crop turnover.

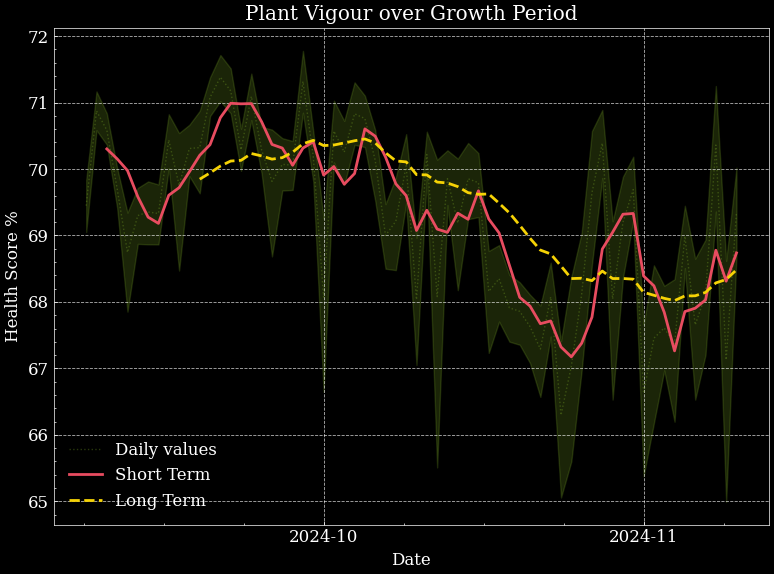

HEALTH

Robust and healthy plants form the foundation of every successful growing season. However, unexpected weather, disease, or system malfunctions can severely disrupt normal greenhouse operations. Detecting these problems early is a critical responsibility for growers and remains one of the most challenging aspects for autonomous growing systems to replicate effectively.

Chlorophyll fluorescence measures the efficiency of photosynthesis which serves as a highly sensitive indicator of plant health. Researchers worldwide rely on it because it can detect both biotic and abiotic stress more than two weeks before visible symptoms appear.

Gardin's HEALTH metric enables growers to monitor plant performance and assess the effectiveness of their cultivation strategies. This capability is especially important for autonomous control systems, where safeguards are needed to ensure algorithms prioritise long-term plant health rather than short-term productivity that could lead to future decline.

Balancing immediate yield gains with sustained crop vitality is the core value of the Gardin HEALTH score. In the Autonomous Greenhouse Challenge, the HEALTH metric remained moderately high through most of the season but began to decline during the final month. Gardin's complementary plant indicators will help explain the causes behind this change.

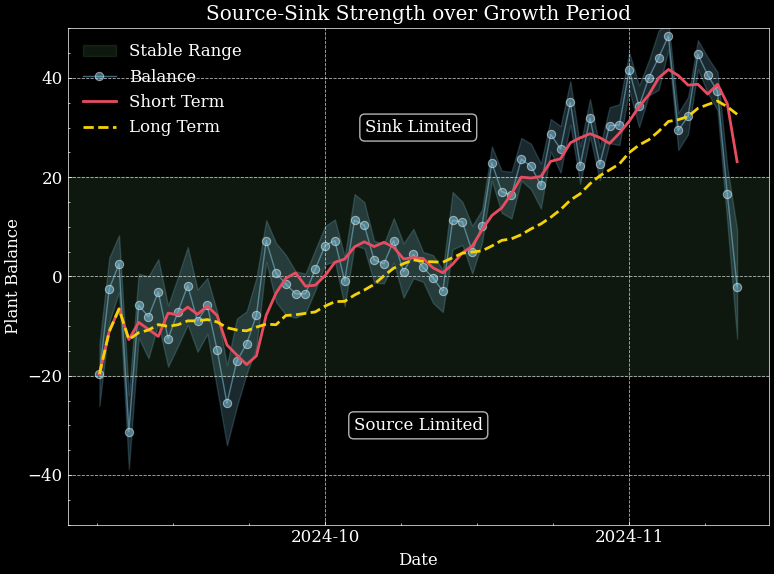

BALANCE

Managing source–sink balance is one of the most challenging aspects of controlling fruiting crops. By the time visible changes appear in the plant, corrective action is often too late. Control algorithms should continuously assess the crop's physiological state and determine whether to promote vegetative or generative growth.

Gardin's BALANCE indicator provides a continuous measure of the source–sink relationship within the plant. A balanced crop scores 0; positive values indicate sink limitation (insufficient demand for assimilates), while negative values indicate source limitation (insufficient photosynthetic supply). The objective is to regulate daily photosynthesis and temperature so that assimilate production in the leaves matches the growth demands of the fruit.

Growers can use this plant feedback to fine-tune key cultivation parameters such as Daily Light Integral (DLI), min-max temperature, and RTR. In this trial, the decline in HEALTH during the final month coincided with a spike in BALANCE, suggesting sink limitation. This occurred as fruits reached full ripeness and no longer required as many assimilates.

However, similar to the delayed harvesting, conservative safety constraints in the algorithm maintained an excessively high DLI, which, combined with suboptimal irrigation led to stress. Future implementations could leverage BALANCE more directly to regulate RTR and reduce reliance on rigid human-imposed guardrails.

EFFICIENCY

Supplemental lighting represents the largest operational cost for greenhouse production during winter. Yet understanding how plants respond to artificial light remains one of the most complex aspects of crop management.

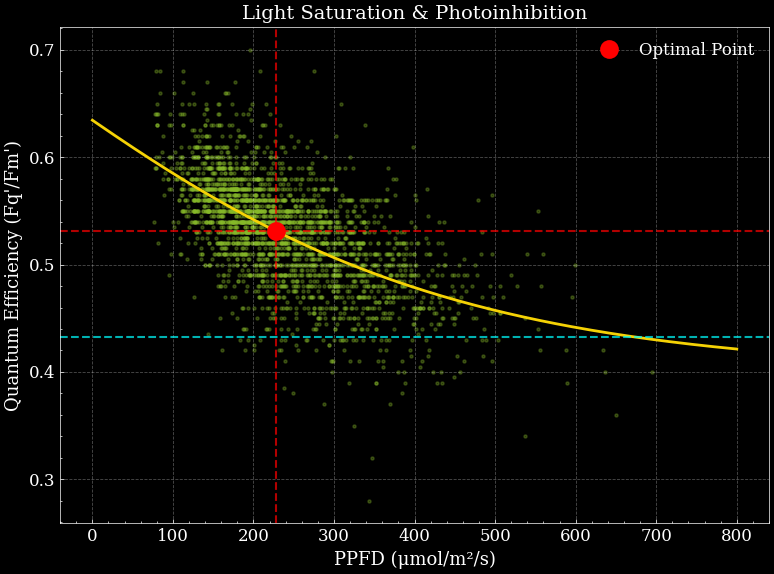

Gardin's EFFICIENCY quantifies the ability of plants to convert light energy into sugars in photosynthesis. As light intensity increases, efficiency naturally declines; however, plants still require sufficient light to sustain optimal growth rates.

The balance between these opposing effects defines the light saturation point - the most efficient PPFD level for light conversion. Beyond this point, additional light delivers diminishing returns.

When sunlight provides the illumination, exceeding this optimal intensity is not necessarily problematic, as natural light does not incur additional cost and enhances photosynthesis. However, if light intensity becomes excessive, plants experience photoinhibition, where the photosynthetic machinery is damaged by overexposure.

Gardin identifies both the light saturation point and the photoinhibition threshold, allowing growers to evaluate and fine-tune their lighting strategies. In the Autonomous Greenhouse Challenge, a plant light-response model was used to dynamically control LED lamp intensity and shading to maximise the return on lighting investment.

PRODUCTIVITY

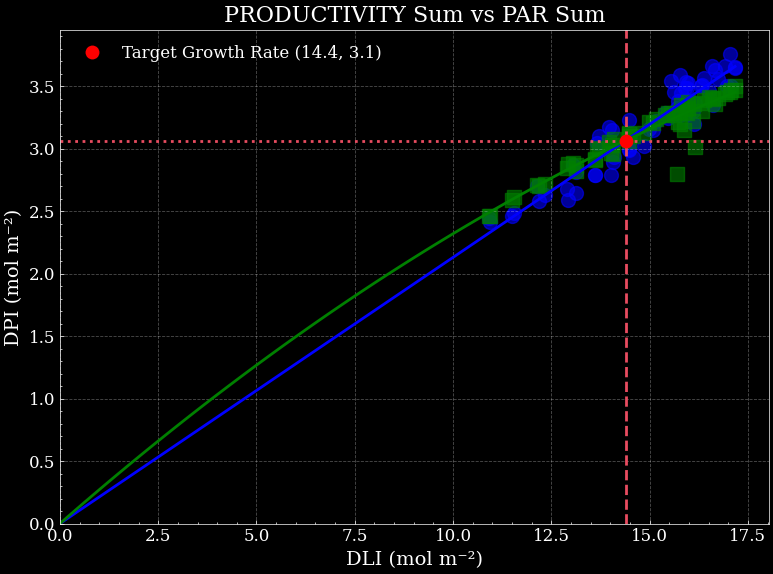

Determining the most cost-effective plant growth rate is a critical decision. Most growers use a target Daily Light Integral (DLI) combined with a 24-hour temperature to maintain a consistent Radiance-Temperature Ratio (RTR), which regulates plant growth rate. However, identifying the optimal DLI for efficient cultivation remains difficult to predict. Growers currently rely on experience, assessing crop health and fruit load to guide their strategy.

Gardin supports growers by using photosynthesis as a direct measure of crop performance. PRODUCTIVITY quantifies the conversion of light into chemical energy, producing assimilates for growth. Summed over the day, PRODUCTIVITY gives the Daily Photosynthesis Integral (DPI). By analysing the relationship between DPI and DLI, Gardin can identify the most cost-effective growth rate for any species or variety.

This approach was applied in the Autonomous Greenhouse Challenge to define the overall cultivation strategy. The DPI-DLI relationship was used to determine the target light sum, whilst established RTR values for cherry tomatoes provided the 24-hour temperature target.

A temperature target informs the heating, ventilation, and shading strategy. In addition, PRODUCTIVITY can be used to optimise set-points for climate variables such as CO₂ and VPD, helping to avoid photosynthetic limitations.

Conclusion

Team MuGrow took part in the Autonomous Greenhouse Challenge to demonstrate the value of plant feedback, with 30% yield increases compared to standard growing practices.

Julian Godding, Head of Science at Gardin, considers the impact of the project results for growers today - "Chlorophyll fluorescence is one of the most powerful indicators to track plant performance in real time. Gardin's technology brings this capability into the modern greenhouse, delivering simple insights to growers that assist their cultivation".

Robert D. McAllister, assistant professor in the Delft Center for Systems and Control and leader of Team MuGrow, considers plant measurements to be a key component of the team's success - "Reliable feedback is often the most important component of any control algorithm; if you cannot measure it, you cannot control it. Gardin's sensor provided an entirely new type of biofeedback, allowing MuGrow to design a uniquely intelligent greenhouse control algorithm that would be otherwise inconceivable."

While full autonomy is still emerging, Gardin's sensors are already deployed in greenhouses across the world today. By leveraging the Gardin Plant Indicators, growers are using feedback from their plants to constantly improve their cultivation and drive the next iteration of horticulture.

To start your journey towards understanding your plants better, please contact us to start the sales process.

RELATED CASE STUDIES

Detected stress within 48 hours of temperature reduction

Critical insights into energy savings and plant performance

34% Gain in Packable Yield

Should your case study be featured here?

Speak to our team to find out what Gardin Pulse will unlock for you.

Contact sales